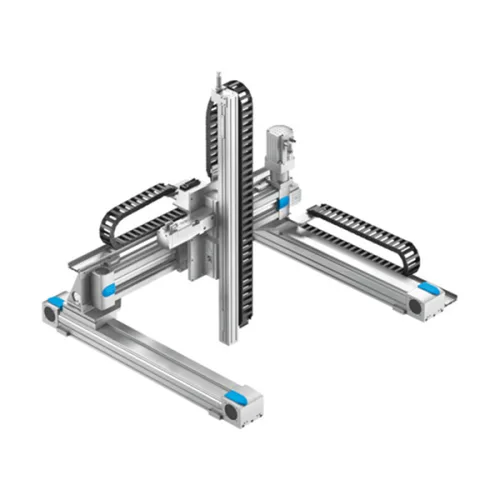

FESTO Handling & Robotics Systems combine innovative mechanical design, intelligent control, and modular construction to deliver flexible automation solutions. The product range includes gantry systems, Cartesian robots, delta robots, articulated robots, and linear actuators designed for high-speed, high-precision applications. With scalable architectures, integrated sensors, and advanced motion controllers, these systems enable fast, repeatable, and safe operation in industries such as packaging, assembly, electronics, automotive, and medical technology. FESTO’s solutions emphasize energy efficiency, ease of integration, and Industry 4.0 connectivity, helping manufacturers increase throughput while maintaining consistent quality and reliability.

- System Types: Cartesian gantry systems, delta robots, articulated robots, linear axes, and integrated handling units.

- Payload Capacity: From a few grams to 50 kg or more, depending on system design.

- Reach/Stroke: Linear and rotational axes with travel distances from 100 mm to several meters.

- Speed & Acceleration: High-speed movement with precise repeatability; acceleration configurable based on application.

- Positioning Accuracy: Repeatability typically within ±0.02 mm to ±0.1 mm, depending on system.

- Control & Communication: Compatible with FESTO controllers and standard industrial protocols (EtherCAT, PROFINET, Ethernet/IP).

- Materials: Aluminum, stainless steel, and lightweight composites for reduced inertia and durability.

- Temperature Range: Operating typically from 0°C to +50°C (higher/lower on request).

- Applications: Pick-and-place, assembly, sorting, packaging, inspection, material handling, and collaborative robotics.